Why Your Commercial Gate’s Reliability Matters for Your Business

Commercial gate repair is a critical service for any business that relies on automatic gates for security and access control. When your gate malfunctions, it doesn’t just inconvenience people—it can disrupt operations, delay deliveries, and create serious security vulnerabilities.

Quick Answer: What You Need to Know About Commercial Gate Repair

- Common Issues: Gates won’t open/close, strange noises, jerky movement, sensor failures, physical damage.

- Response Time: Most professional services offer 24-72 hour turnaround, with same-day emergency options.

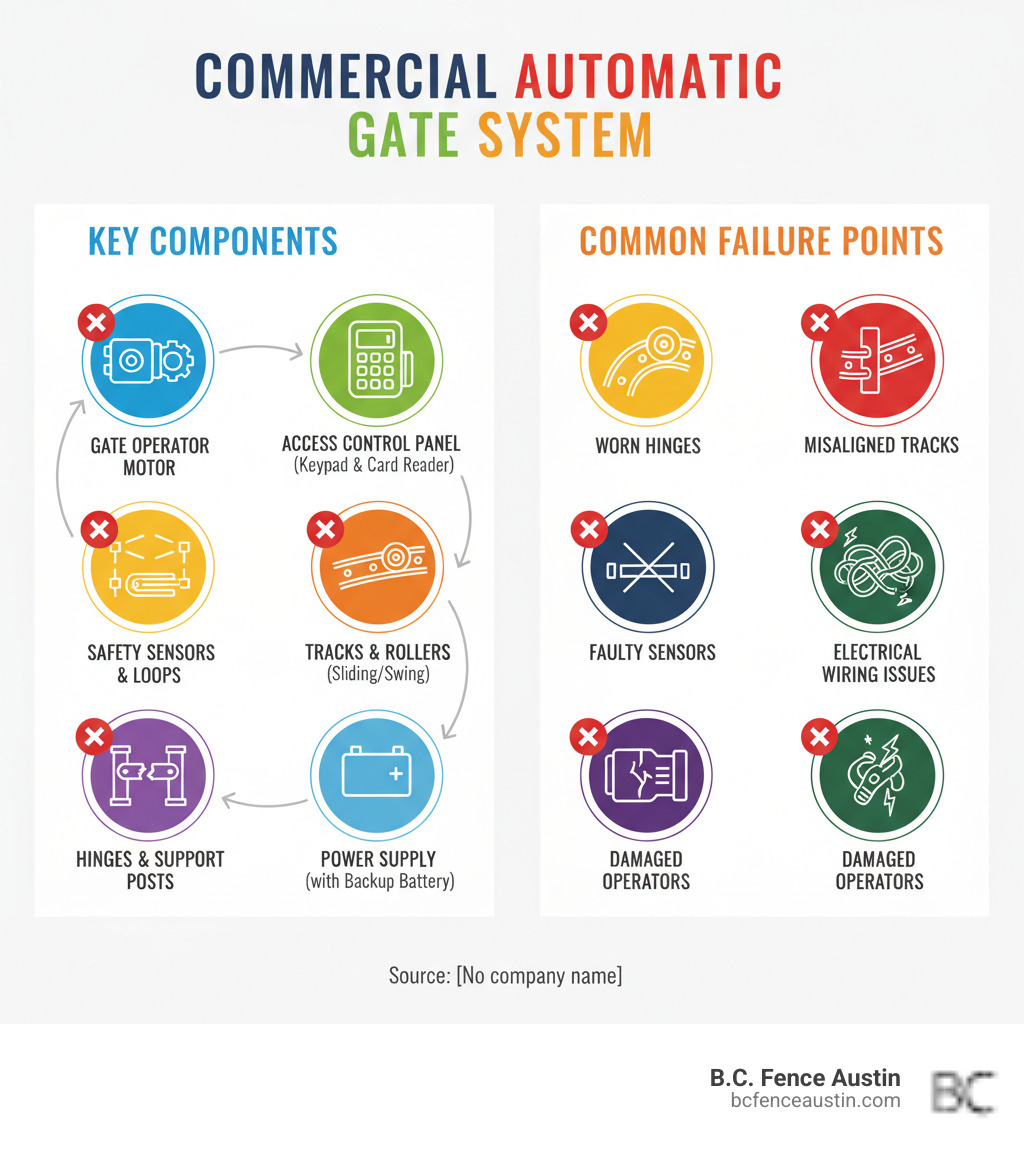

- Key Components: Gate operators (motors), tracks, hinges, access controls, safety sensors, wiring.

- When to Call: Immediately upon noticing strange noises, visible damage, or inconsistent operation.

- Maintenance Schedule: Professional inspection is recommended every 12 months.

Your commercial gate endures thousands of cycles annually, facing wear from heavy use, weather, and occasional vehicle impacts. Research indicates that gated security systems can reduce burglary by 33%—but only when they function correctly.

A broken gate can severely impair business operations, slowing deliveries and leaving your property vulnerable. The good news is that most issues can be diagnosed and repaired quickly by experienced technicians. Whether it’s a sliding gate with bent tracks or a swing gate with a compromised operator, professional repair restores your security and keeps your business running smoothly.

Recognizing the Red Flags: Signs Your Commercial Gate Needs Attention

When your commercial gate has a problem, it usually provides warning signs. Recognizing these signs early can prevent a minor issue from becoming a major operational nightmare. Think of commercial gate repair as preventative medicine for your business; catching issues early saves you money and downtime.

- Visible damage: Scratches, dents, or rust often signal deeper structural issues that can lead to costly future repairs.

- Grinding, scraping, or squealing noises: These sounds point to worn rollers, loose chains, or misaligned tracks, indicating friction that is wearing down components.

- Jerky, sluggish, or hesitant operation: A healthy gate glides smoothly. Stuttering or slow movement may indicate operator malfunctions or electrical issues.

- Gate won’t open or close completely: This is a critical failure that stops your business in its tracks, blocking access and leaving you vulnerable. It’s often caused by power failures, faulty motors, or misaligned sensors.

- Misaligned gate: A sagging or leaning gate puts immense stress on all other components, leading to damaged tracks and failed hinges.

- Sensor malfunctions: This is a serious liability issue. When safety sensors fail, your gate might close on vehicles or people, creating a dangerous situation.

- Unresponsive access controls: If keypads, card readers, or remotes stop working, authorized personnel can’t get in, disrupting your entire business day.

Common Causes of Gate Malfunctions

Understanding the root cause of a malfunction can help prevent future problems.

- Daily wear and tear: Constant movement creates stress on moving parts like hinges, rollers, and the gate operator, causing them to wear down over time.

- Vehicle impacts: Even a minor collision can bend tracks, damage operators, or compromise the gate’s structural integrity.

- Severe weather damage: High winds, heavy rain, and temperature extremes in Austin take their toll, causing corrosion and frying electrical systems.

- Electrical faults: Frayed wiring, power surges, or faulty circuit boards can cause your gate to stop working or behave erratically.

- Pest infestations: Rodents and insects can chew through wires and build nests inside control boxes, causing electrical shorts.

- Misaligned tracks or posts: Ground settlement or vehicle damage can knock components out of alignment, putting excessive strain on the motor.

- Lack of lubrication: Hinges, rollers, and chains require regular lubrication to move smoothly. Without it, parts seize up and fail.

For more information on how we design gates built to handle these challenges, check out our custom gates.

Understanding Your System: Key Components and Common Gate Types

Knowing the basics of your commercial gate system helps you describe symptoms clearly to a repair technician, leading to a faster diagnosis. Your automatic gate is a complex system of mechanical and electrical components, and when one part fails, the entire system suffers.

Anatomy of an Automatic Gate System

- Gate operator (motor): The muscle that moves the gate. Motor burnout, stripped gears, or electrical failures will leave your gate immobile.

- Access control panel: The brain of the system, including keypads, card readers, and remotes. Malfunctions mean a loss of access control.

- Safety sensors: Photocells and loop detectors are the gate’s eyes, preventing it from closing on people or vehicles. When they fail, the gate can become a safety hazard.

- Tracks, rollers, and wheels: For sliding gates, these parts ensure smooth movement. Bent tracks or worn rollers cause grinding noises and jerky operation.

- Hinges and support posts: For swing gates, these components bear the gate’s full weight. Worn hinges or leaning posts cause the gate to drag and strain the motor.

- Power supply and backup battery: This system provides electricity to the motor and controls, with a battery to ensure operation during a power outage.

If you’re considering a new gate system that integrates all these components seamlessly, check out our Custom Entry Gates to see what’s possible with modern automation.

Types of Commercial Gates and Their Repair Needs

Different gate styles have unique repair needs.

- Sliding gates: Ideal for tight spaces, they glide horizontally. Common repairs involve bent tracks, worn rollers, and motor issues.

- Swing gates: Operating like doors on hinges, they often need repairs for hinge wear, operator failure, and frame damage.

- Cantilever gates: These slide open without a ground track, making them great for uneven ground. Repairs often focus on the specialized rollers and counter-balance system.

- Barrier arm gates: Used for high-traffic vehicle control, the arm is vulnerable to impact damage, and the motor can wear out from constant use.

- Vertical lift gates: Perfect for tight spaces, these gates lift straight up. Repairs center on the lifting mechanism, cables, and motor.

- Roll-up gates: Functioning like garage doors, they are prone to spring tension issues, damaged slats, and track problems.

No matter which type of gate protects your business, our technicians have seen it all. We understand the unique vulnerabilities and common failure points of each design.

The Professional Commercial Gate Repair Process

When your commercial gate fails, you need a methodical repair process that gets you back to business quickly and safely. Our approach to commercial gate repair is refined to be thorough, safe, and lasting.

Step 1: Diagnosis and Safety Assessment

Our first step is detective work. Our certified technicians perform a thorough inspection of the entire system to troubleshoot the root cause of the malfunction, not just the obvious symptom. We identify all worn or broken parts, and because our service vehicles are well-stocked, we can often complete repairs in a single visit. Before any work begins, we secure the work area and perform electrical safety checks, adhering to strict industry protocols.

Step 2: Executing the Commercial Gate Repair

With the diagnosis complete, our technicians get to work restoring your gate’s function. This may involve:

- Component replacement: Swapping out failed parts like motors, circuit boards, or sensors with high-quality replacements.

- Hinge welding repair: For swing gates, we can perform on-site welding to restore structural strength without a full replacement.

- Track realignment: We precisely adjust and re-secure sliding gate tracks to ensure smooth, quiet operation and reduce motor strain.

- Motor and gearbox service: We diagnose and repair complex mechanical and electrical issues within the gate operator unit.

- Fixing access control wiring: Our team repairs damaged connections and troubleshoots communication issues between your access system and the gate.

If you’re curious about how we approach new installations with the same attention to detail, check out More info about our Gate Installation Services.

Step 3: Testing and Final Walkthrough

Before we consider the job done, we verify that everything works perfectly. We conduct full system testing, running the gate through multiple open-and-close cycles using every access method. Safety feature verification is critical; we rigorously test all sensors to ensure they prevent the gate from closing on an obstacle. We perform a final check of the gate’s balance and alignment to ensure it moves freely without straining the motor. Finally, we provide customer training on the repairs and any new components, ensuring you feel confident in your gate’s operation.

Proactive Protection: Maintenance and Choosing a Provider

Fixing a broken gate is a necessity, but preventing it from breaking is smart business. Regular check-ups can catch small issues before they become emergencies. Here’s how to keep your gate healthy and find the right partner to help.

How Preventative Maintenance Avoids Costly Repairs

An ounce of prevention is worth a pound of cure, especially with commercial gate repair. Regular maintenance is your best defense against unexpected failures. It extends your gate’s lifespan, ensures reliable operation, improves safety, reduces downtime, and saves money by catching small issues before they become costly emergencies. We recommend professional maintenance at least once a year, or semi-annually for high-traffic gates.

A typical maintenance visit includes:

- Lubricating all moving parts (hinges, rollers, chains)

- Inspecting and cleaning tracks of debris

- Testing the motor for signs of strain

- Verifying all safety sensors are responsive

- Checking and correcting gate alignment

- Inspecting electrical wiring for wear or damage

For a comprehensive look at how we can help maintain your entire commercial property, explore our Guide to Commercial Fence Services Austin.

Choosing the Right Commercial Gate Repair Service

Choosing the right partner is about finding a team you can trust with a critical part of your business. Here’s what to look for:

- Experience and certifications: Look for companies with decades of experience and certified technicians who receive ongoing training.

- 24/7 emergency availability: Gate problems don’t keep business hours. Ensure your provider offers round-the-clock service for urgent security issues.

- Fast response times: Look for same-day emergency service and a 24-72 hour window for standard repairs to minimize disruption.

- Warranties and guarantees: A reputable company will offer a warranty on parts and labor, showing they stand behind their work.

- Local expertise: A local provider understands Austin’s climate and building codes, ensuring durable repairs and faster response.

- Comprehensive service: Choose a company that can handle all types of repairs and carries a wide range of parts for on-the-spot fixes. For more guidance, you can review these tips for hiring a contractor from the Federal Trade Commission.

When you’re ready to discuss your commercial fencing and gate needs with a team that understands Austin businesses, remember we’re experienced Commercial Fence Contractors who’ve been serving this community for years.

Frequently Asked Questions about Commercial Gate Repair

We hear a lot of the same concerns from business owners when their gates start acting up. Here are the questions that come up most often, with straightforward answers.

How often should a commercial gate be serviced?

We recommend professional maintenance at least once a year for most commercial gates. For high-traffic gates, such as those at busy industrial facilities or parking garages, semi-annual service is better to ensure reliability and safety. Regular check-ups catch problems before they cause a complete breakdown.

Is it better to repair or replace a damaged commercial gate?

This depends on the gate’s age, the extent of the damage, and the cost. Repairing a single component like a motor or hinge is often the most economical choice. However, for older, structurally compromised, or extensively rusted gates, replacement can be a smarter long-term investment. Our technicians will provide an honest assessment to help you decide.

Why is timely repair so important for a business?

A malfunctioning gate is a major liability. Timely commercial gate repair is crucial for three reasons:

- Security: A broken gate that won’t close leaves your property vulnerable to theft and vandalism. That 33% reduction in burglary risk from a gated system only applies when the gate is actually secure.

- Operations: A gate stuck shut blocks deliveries, employees, and customers, grinding your business to a halt. This means lost productivity and potential revenue.

- Safety: A gate with malfunctioning sensors can close unexpectedly on people or vehicles, creating a serious safety hazard and a huge liability.

Addressing issues promptly prevents these problems and stops minor issues from escalating into expensive failures.

Conclusion: Secure Your Operations with a Trusted Partner

Your commercial gate is a critical asset that protects your property, controls access, and keeps your business running. A breakdown instantly highlights its importance, creating security risks and operational chaos.

Professional commercial gate repair ensures both safety and security. When you work with experienced technicians, you get a thorough diagnosis, quality parts, and the peace of mind that the job was done right. Our team has the tools and expertise to handle everything from simple hinge replacements to complex electrical troubleshooting.

Furthermore, preventative maintenance is a smart investment that pays for itself by extending your gate’s lifespan and preventing costly emergency repairs. It’s insurance for your operations.

For businesses in Cedar Park, Austin, Leander, Round Rock, Georgetown, and Pflugerville, having a local partner who understands our climate and commercial demands is essential. We are committed to keeping your gate—and your business—running smoothly.

Whether you have a gate emergency or want to schedule maintenance to avoid future issues, we’re here to help. Contact us for commercial gate services in Cedar Park and experience the B.C. Fence Austin difference. Your gate works hard for you—let us make sure it keeps doing its job.