Why Barbed Wire Fencing Changed America Forever

Barbed wire fencing revolutionized American agriculture and land ownership in the 1870s, changing the open range into organized property boundaries. This simple yet ingenious invention consists of twisted steel wire with sharp barbs spaced at regular intervals, designed to contain livestock while deterring intruders.

Key Facts About Barbed Wire Fencing:

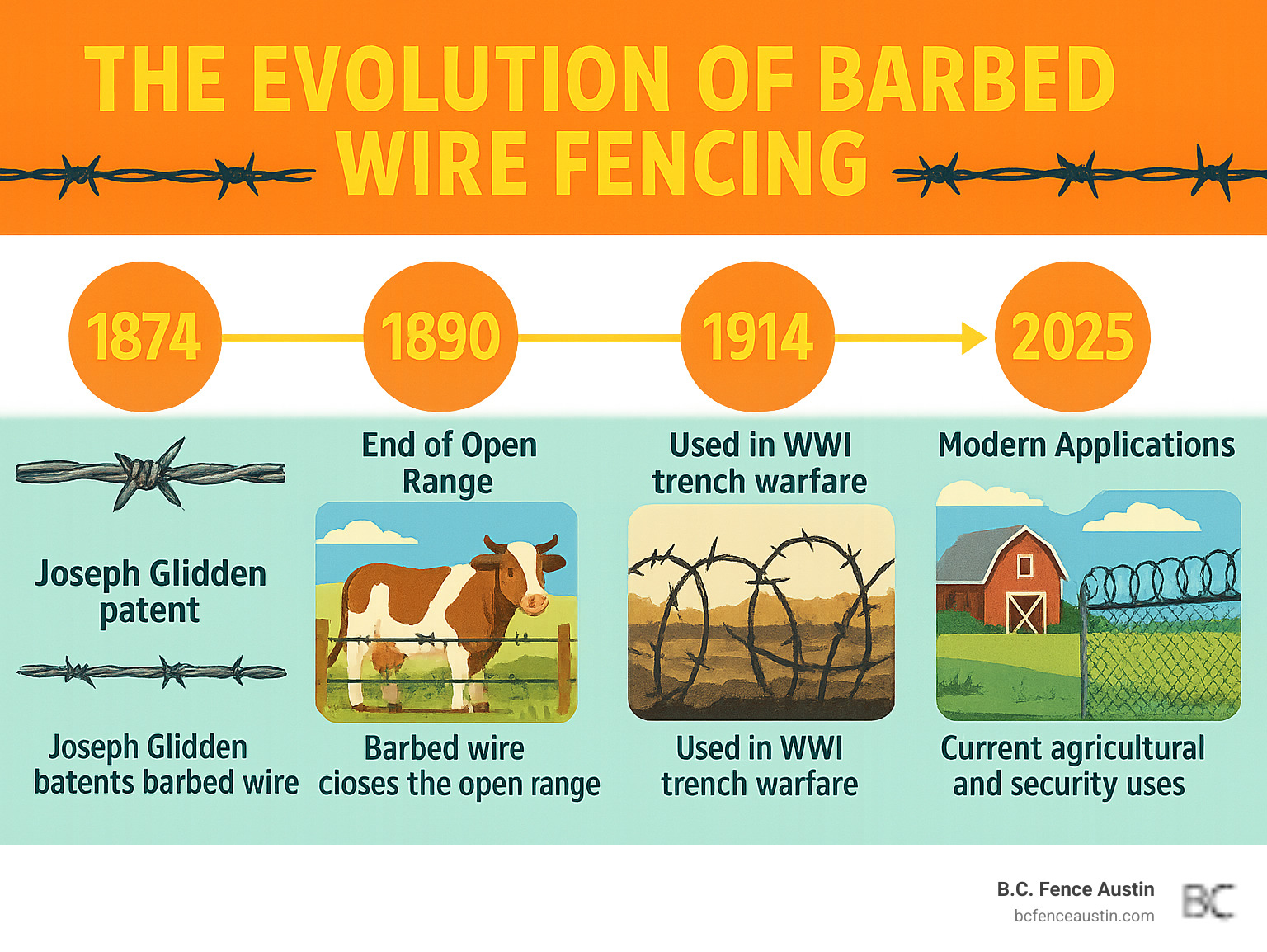

- Invented: 1874 by Joseph Glidden

- Materials: Low-carbon steel wire with zinc coating

- Barb Types: 2-point or 4-point configurations

- Standard Spacing: 4-5 inches between barbs

- Lifespan: 20-50 years with proper maintenance

- Common Uses: Livestock containment, property boundaries, security applications

In the mid-1800s, the invention of barbed wire changed the landscape of the western prairies forever. What started as a solution for farmers struggling to contain cattle on the open range became the backbone of modern agriculture and security fencing.

Joseph Glidden’s 1874 patent for “The Winner” barbed wire fencing design proved so effective that by 1880, more than 80 million pounds of his wire had been sold across America. This “devil’s rope,” as some called it, ended the era of open-range cattle drives and sparked conflicts known as the Fence Cutting Wars.

Today, barbed wire remains the most widely used agricultural fencing in the United States. Its low cost, durability, and effectiveness make it a practical choice for ranchers, farmers, and property owners who need reliable perimeter protection.

Key terms for barbed wire fencing:

From Prairie to Perimeter: The History of Barbed Wire

Picture the American West in the 1860s: endless prairies stretched as far as the eye could see, with cattle roaming freely across unfenced land. Ranchers faced a massive challenge – how do you contain thousands of head of cattle without spending a fortune on wooden fences that would take years to build?

The answer came from an unlikely source: a farmer’s ingenuity and a few twisted wires.

Before barbed wire fencing changed everything, the open range was exactly that – open. Cowboys drove massive herds hundreds of miles to market, following ancient trails across land that belonged to everyone and no one. Traditional fencing methods like stone walls or wooden rails worked fine for small farms back East, but they were completely impractical for the vast expanses of the American frontier.

Then in 1874, Joseph Glidden, a farmer from Illinois, received a patent that would literally reshape America. His brilliant innovation wasn’t just adding sharp barbs to wire – it was figuring out how to keep those barbs exactly where they needed to be. By twisting two strands of wire together in opposite directions, he created a system where the barbs stayed put, creating the first truly effective barbed wire fencing.

The impact was nothing short of revolutionary. Suddenly, ranchers could fence thousands of acres quickly and affordably. The invention that tamed the West spread like wildfire across the plains. Within just six years, over 80 million pounds of Glidden’s wire had been sold.

But this rapid change came with a price. The famous Fence Cutting Wars of the 1880s erupted as old-time ranchers who depended on open grazing land clashed with newcomers who were fencing off water sources and traditional cattle routes. It was a battle between the old way of doing things and progress – and progress won.

The story of barbed wire fencing didn’t end on the prairie, though. During World War I, this simple farming tool took on a much darker role in the trenches of Europe. Its effectiveness as a barrier made it a grim symbol of modern warfare. Today, it continues to evolve, serving everything from basic livestock containment to high-security perimeter defense at industrial facilities.

The Anatomy of Barbed Wire

Understanding what makes barbed wire fencing so effective starts with appreciating its deceptively simple design. At first glance, it might look like just twisted wire with sharp bits attached, but there’s actually some clever engineering at work here.

The foundation of most barbed wire is the double-strand design. Two separate wires get twisted together to form a strong cable that holds everything together. This isn’t random twisting either – the best designs use a reverse twist pattern where the wires spiral in opposite directions. This creates a fence line that’s stronger, resists sagging, and has what we call “memory” – it bounces back to its original shape instead of staying stretched out.

The wire itself is typically made from low-carbon steel, which gives you the perfect balance of strength and flexibility. But here’s where things get really smart: that steel gets put through a galvanization process where it’s coated with zinc. Think of the zinc as a bodyguard for the steel – it takes the hit from rust and corrosion so the wire underneath stays strong for decades.

This protective coating is what separates quality barbed wire fencing from the cheap stuff that falls apart after a few years. The zinc literally sacrifices itself to keep your fence intact, which is why proper galvanization matters so much for longevity. For more detailed information about different fence materials and their properties, you can check out more info about fence materials.

Types and Specifications

Not all barbed wire fencing serves the same purpose, and choosing the right type can make the difference between a fence that lasts decades and one that needs constant repairs. Let’s break down the key specifications that matter most.

Barb configurations come in two main varieties. 2-point barbs feature two sharp points extending from the wire – these work great for general livestock containment where animals have plenty of room to move around. 4-point barbs step up the deterrent factor with four sharp points, making them ideal for situations where animals might crowd against the fence or where you need maximum security.

Wire gauge refers to thickness, and here’s where it gets a bit backwards – smaller numbers mean thicker, stronger wire. 12.5-gauge wire is the heavy-duty option, often meeting military specifications and perfect for high-stress applications. 15.5-gauge wire is lighter but can still be very effective, especially when it’s made from high-tensile steel that delivers strength without the extra weight.

Barb spacing typically runs either 4 inches or 5 inches apart. The standard 5-inch spacing works fine for most situations, but when you’re dealing with determined animals or need to keep wildlife out, that tighter 4-inch spacing creates a more formidable barrier.

The coating quality determines how long your fence will last. Class 1 galvanization provides good rust resistance for most applications, while Class 3 coating offers significantly more zinc protection – think of it as the premium option that pays for itself over time through reduced maintenance and longer life.

You’ll also find vinyl-coated options where the wire (though usually not the barbs) gets wrapped in colored vinyl for extra protection and a cleaner appearance. High-tensile wire represents the latest advancement, using higher carbon content to create wire that’s both lighter and stronger than traditional options, requiring fewer materials for the same level of performance.

A Practical Guide to Barbed Wire Fencing Installation

Let’s be honest – installing barbed wire fencing isn’t exactly a Sunday afternoon stroll in the park. Those sharp barbs mean business, and they don’t care if you’re wearing your favorite shirt. But with the right approach, you can tackle this project safely and end up with a fence that’ll serve you well for decades.

The secret to successful barbed wire fencing installation lies in four key areas: putting safety first, planning every detail, understanding how tension works, and building something that’ll last. Rush any of these, and you’ll likely find yourself redoing the work – or worse, nursing some painful cuts.

Planning Your Project

Think of planning your barbed wire fencing project like mapping out a road trip – you wouldn’t just hop in the car and hope for the best, would you? The same logic applies here.

Start by calculating exactly how much wire you’ll need. Walk your property line and measure the perimeter carefully. Once you have that number, multiply it by however many strands you’re planning to run. Planning a 4-strand fence around 500 feet of property? You’ll need 2,000 feet of wire. Most barbed wire fencing comes in quarter-mile rolls (that’s 1,320 feet), so you can figure out how many rolls to buy.

But wire is just the beginning. You’ll also need fence posts – whether you go with sturdy wooden posts or practical T-posts depends on your budget and soil conditions. Don’t forget the hardware either: staples for wooden posts, clips for T-posts, and any bracing materials for corners where the real stress happens.

Here’s something many folks overlook until it’s too late: checking local zoning laws and regulations. Whether you’re in Cedar Park, Austin, or anywhere in between, rules about fence height, placement, and materials can vary dramatically. Some neighborhoods have strict guidelines, especially about how close to property lines you can build. A quick call to your city office can save you major headaches later.

For comprehensive guidance on protecting your property boundaries, take a look at our resources on fence perimeter protection.

Installation Best Practices

Now for the fun part – actually putting up your barbed wire fencing! But before you touch a single strand of wire, let’s talk safety gear. This isn’t the time to cut corners.

You’ll absolutely need heavy-duty leather gloves – those thin gardening gloves won’t protect you from sharp barbs. Eye protection is non-negotiable because wire under tension can snap unexpectedly. Long sleeves and pants protect your skin from scrapes, and sturdy work boots keep your feet safe if you drop tools or step on wire scraps.

Post selection makes or breaks your fence’s longevity. Wooden posts offer superior strength, especially for corners and bracing, while metal T-posts work well for line posts between corners. The key is understanding where each type works best.

Corner and brace posts are the backbone of your fence system. These posts handle enormous tension from stretched wire, so they need to go deep – typically 2 to 3 feet, depending on your fence height and soil type. Proper bracing using diagonal or horizontal supports distributes that tension and prevents sagging over time.

For line posts, spacing matters more than you might think. With cattle or other large livestock, 12 feet apart works well. For smaller animals or areas where crowding happens, stick to 8 to 10 feet apart. On hilly or uneven ground, place posts closer together and make sure you have one at the top of each rise to maintain consistent wire height.

Stretching and tensioning the wire separates amateur jobs from professional ones. You’ll need a wire stretcher or come-along tool to pull the wire taut without overdoing it. Too loose, and animals will push through. Too tight, and temperature changes will snap your wire. Always run the wire on the inside of posts so animal pressure pushes wire into posts rather than away from them.

Finally, attaching wire to posts requires the right technique. For T-posts, use clips designed for the job. For wooden posts, hammer staples at a slight vertical angle with the short end pointing up, but don’t drive them completely flush. This allows for slight movement and makes retightening easier down the road.

Want to dive deeper into the technical aspects? Check out this comprehensive guide on how to build a barbed wire fence for additional professional insights.

Applications, Durability, and Safety

Barbed wire fencing has proven itself time and again as one of the most versatile fencing solutions available. What started as a simple way to keep cattle from wandering has evolved into a trusted security measure across countless industries. Its enduring popularity comes down to three key strengths: versatility, impressive longevity, and when properly managed, reliable performance for decades.

Common Applications of Barbed Wire Fencing

The agricultural world still relies heavily on barbed wire fencing, and for good reason. When it comes to cattle and livestock containment, nothing beats its combination of effectiveness and practicality. A standard 4 to 5-strand fence, standing about 42 to 48 inches high, works beautifully for cattle and horses. These larger animals generally respect the boundary once they’ve had their first gentle reminder from the barbs.

Smaller livestock like sheep, goats, and pigs require a bit more persuasion. These clever escape artists often need 6 to 7 strands with posts placed closer together. It’s amazing how determined a pig can be when there’s something interesting on the other side of the fence! We’ve helped many farmers protect their livestock with a fence that matches their specific animals’ personalities and behaviors.

Property demarcation is another natural fit for barbed wire. When you own acres of land, clearly marking your boundaries prevents neighborly disputes and keeps everyone on the same page. It’s straightforward, visible, and legally recognized – three things every property owner appreciates.

The security world has also acceptd barbed wire fencing in a big way. Industrial and commercial security applications have grown tremendously over the years. Construction sites, warehouses, and manufacturing facilities often turn to barbed wire as their first line of defense against deterring trespassers. There’s something about those sharp barbs that makes people think twice about climbing over.

Many businesses take security a step further by installing barbed wire fencing on top of existing chain link or masonry walls. This creates what security professionals call a “layered defense” – multiple obstacles that make unauthorized entry much more challenging and risky.

Maintenance and Safety for Barbed Wire Fencing

One of the most impressive things about barbed wire fencing is its remarkable staying power. With proper installation and basic care, you can expect your fence to serve faithfully for 20 to 50 years. We’ve even seen some well-maintained fences that have been standing strong for over 70 years – now that’s what we call a solid investment!

Several factors influence durability, and understanding them helps you get the most from your fence. The quality of materials matters enormously – Class 3 galvanization provides superior rust resistance compared to basic coatings. Your local climate plays a role too, with coastal areas and regions with harsh winters requiring more attention. Most importantly, regular maintenance and material quality work hand in hand to extend your fence’s life.

The good news is that maintenance is pretty straightforward. Regular inspection means walking your fence line occasionally to spot loose strands, damaged posts, or areas where tension needs adjustment. Catching these small issues early prevents them from becoming expensive problems later.

However, we always emphasize the importance of handling with care when working around barbed wire fencing. Those barbs that make it so effective also create potential dangers to humans and animals. Cuts, punctures, and scrapes are real risks if you’re not properly prepared.

Safety gear isn’t optional – it’s essential. Heavy leather gloves, long sleeves, sturdy boots, and eye protection should be standard equipment for anyone working with barbed wire. Even routine maintenance tasks require this level of preparation.

For animals, particularly sensitive ones like horses, there’s always some risk of injury. This is why many horse owners choose alternative fencing materials. Understanding your animals’ behavior and choosing the right fencing solution for their specific needs is part of responsible ownership.

The OSHA safety guidelines provide excellent guidance on proper handling techniques and protective equipment. Following these recommendations helps ensure that your barbed wire fencing project stays safe from start to finish.

Frequently Asked Questions about Barbed Wire

People often ask us about barbed wire fencing, and honestly, we love talking about it! After years of installing fences across Central Texas, we’ve heard just about every question you can imagine. Let’s explore the most common ones.

How tall should a barbed wire fence be?

The perfect height for your barbed wire fencing really depends on what you’re trying to accomplish. Think of it like choosing the right tool for the job – you wouldn’t use a hammer to fix a watch, right?

For most cattle and livestock containment, we typically install fences between 4 and 5 feet tall. This height works beautifully for cows, who generally respect the barrier once they understand it’s there. Horses might need something a bit different since they can be more curious (and sometimes more athletic) than cattle.

Now, if you’re dealing with deer – those graceful jumpers who treat most fences like problems – you’ll want to go 6 to 8 feet tall. We’ve seen deer clear shorter fences like they’re barely there, so height really matters for wildlife exclusion.

Here’s something important we always tell our customers: check your local regulations first. Whether you’re in Cedar Park, Georgetown, or anywhere else in the Austin area, local ordinances can dictate maximum fence heights. Some areas have specific rules about agricultural versus residential properties, so it’s worth a quick call to your local planning office.

How does barbed wire compare to other farm fences?

This is probably our favorite question because barbed wire fencing really shines when you look at the big picture. Let’s be honest – it’s hard to beat for cost-effectiveness, especially when you’re covering large areas. You can fence acres for a fraction of what other materials would cost.

One thing we love about working with barbed wire fencing is how well it handles varied terrain. Rolling hills, rocky ground, creek beds – it adapts beautifully to the natural landscape. Try doing that with rigid panels, and you’ll quickly see the difference!

Durability is another strong point. A properly installed barbed wire fencing system can last 20 to 50 years, sometimes even longer with quality materials like Class 3 galvanized wire. Compare that to wooden rail fences that might need replacement boards every few years, and the math starts looking pretty good.

Maintenance is refreshingly simple too. You might need to check tension annually and replace an occasional post, but that’s about it. No painting, no replacing rotted boards, no fighting with warped panels.

The main trade-off? It’s not ideal for smaller animals like goats or sheep – they can be escape artists when it comes to barbed wire fencing. For those situations, we might recommend field fencing or other alternatives. Want to explore all your options? Check out our guide on the best options for farm fencing.

Can I use barbed wire for residential fencing?

We get this question more often than you might expect, and our answer is almost always no for residential properties. Here’s why we feel so strongly about this.

Safety is our biggest concern. Those sharp barbs that make barbed wire fencing so effective for livestock can be genuinely dangerous for people, especially children playing in the yard. Pets can also get seriously injured – we’ve seen too many emergency vet visits from curious dogs or cats.

Beyond safety, there’s the legal side. Most residential areas around Austin – including neighborhoods in Pflugerville, Round Rock, and Lago Vista – have strict regulations that either restrict or completely ban barbed wire fencing in residential zones. These rules exist for good reasons: public safety, emergency access, and community standards.

Emergency responders like paramedics and firefighters need quick, safe access to properties. Barbed wire fencing can create dangerous obstacles during emergencies, which is why many municipalities specifically prohibit it in residential areas.

For residential needs, we’re excited to help you explore safer and more attractive alternatives. Chain link offers security without the injury risk, wood privacy fencing creates beautiful boundaries, and ornamental iron can provide both elegance and protection. These options not only keep you compliant with local laws but also improve your property value and curb appeal.

Conclusion

From the dusty cattle trails of the 1870s to today’s high-security facilities, barbed wire fencing has proven itself to be far more than just twisted steel and sharp points. It’s a piece of American history that continues to evolve and serve property owners across the country.

What started as Joseph Glidden’s solution to contain wandering cattle has become one of the most enduring and practical fencing solutions ever created. The same basic design that ended the era of open ranges now protects livestock, secures industrial sites, and defines property boundaries from coast to coast.

The beauty of barbed wire fencing lies in its simplicity and effectiveness. It doesn’t need fancy electronics or complex maintenance schedules. When properly installed with quality materials and attention to detail, it quietly does its job year after year, decade after decade. Whether you’re protecting valuable livestock or securing a commercial property, it offers the reliability that modern property owners demand.

At B.C. Fence Austin, we’ve seen how the right fencing can transform a property. We understand that barbed wire fencing isn’t just about keeping things in or out – it’s about peace of mind. When you know your fence is built to last, you can focus on what matters most to you.

Our team brings decades of experience to every project, whether you’re in Austin, Cedar Park, Leander, Liberty Hill, Round Rock, Georgetown, Pflugerville, Lago Vista, or Jonestown. We take pride in installations that honor the legacy of this remarkable invention while meeting the demands of modern property management.

Ready to experience the time-tested reliability of professional barbed wire fencing? Get a professional barbed wire fence installation and join the countless property owners who’ve finded that sometimes, the old ways really are the best ways.